|

1.Raw-Material Brand: |

DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M |

|

2.Type: |

According to Car Brand |

|

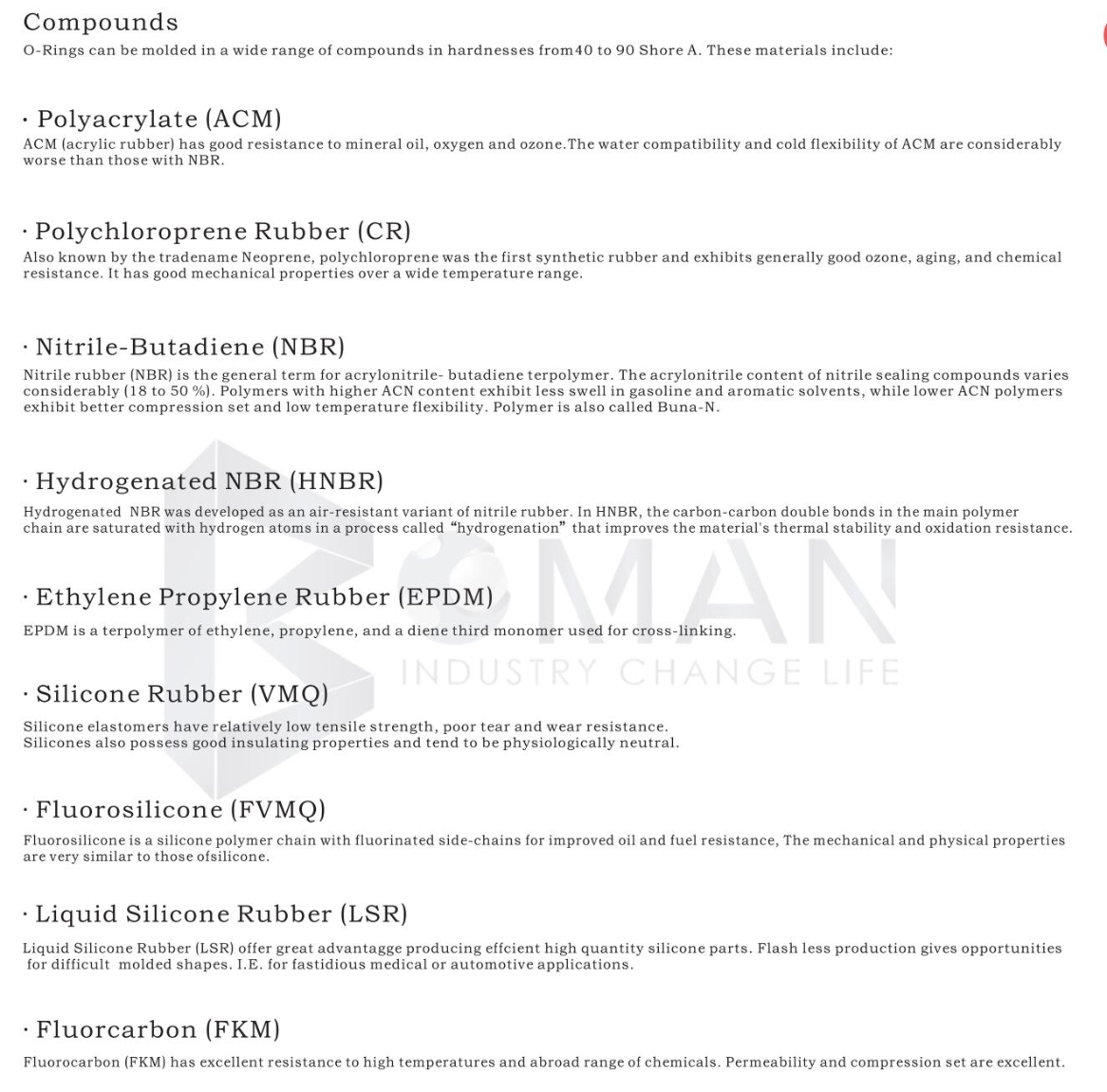

3.Material Type: |

NBR / FKM / Silicone/EPDM/HNBR... |

|

4.Size: |

Standard and Customize |

|

5.Products Application |

Metallurgical, chemical, engineering, construction, mining, petroleum machinery |

|

6.Color: |

Black, white, red, or any customize |

|

7.Parameters: |

Temperature from -60° C to +220° C in different material |

|

8.Factory Certificate |

IATF 16949:2016 and ISO9001, ISO14001 certificated |

|

9.Product Certificate |

KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA |

Valve cover gasket is a crucial component used in internal combustion engines, especially those with overhead camshafts (OHC) or overhead valves (OHV). It is designed to create a reliable and leak-proof seal between the valve cover and the cylinder head of the engine. The valve cover is a protective cover that sits on top of the cylinder head and houses the engine's valves and other components.

1.Oil Leakage Prevention: The primary function of a valve cover gasket is to prevent oil leaks from the top of the engine. It creates a tight seal between the valve cover and the cylinder head, ensuring that engine oil remains contained within the engine and does not leak onto other engine components or the ground.

2.Engine Protection: By preventing oil leaks, valve cover gaskets help protect the engine from potential oil-related issues, such as low oil levels, oil contamination, and engine damage due to insufficient lubrication.

3.Improved Engine Performance: Properly functioning valve cover gaskets contribute to improved engine performance by ensuring that oil is effectively distributed and maintained within the engine. This leads to smoother engine operation and optimal lubrication of the valve train components.

4.Reduced Oil Consumption: Valve cover gaskets play a role in reducing oil consumption by preventing oil leaks and ensuring that the engine retains an adequate oil level. This can lead to longer intervals between oil changes and cost savings on oil.

5.Contaminant Exclusion: Valve cover gaskets help keep contaminants, such as dust, dirt, and debris, out of the engine's valve train area. This ensures that the valves and related components operate smoothly and remain clean, reducing the risk of premature wear.

6.Heat and Chemical Resistance: High-quality valve cover gaskets are designed to withstand the heat and chemicals present in the engine environment. They remain effective and durable even under extreme operating conditions.

7.Easy Replacement: Valve cover gaskets are typically easy to replace when necessary, making maintenance tasks more straightforward and reducing downtime.

8.Vibration Dampening: Some valve cover gaskets have properties that help dampen vibrations and reduce noise in the valve train area, contributing to a quieter engine operation.

9.Longevity: Properly installed and maintained valve cover gaskets can have a long service life, providing continuous sealing protection for extended periods.

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | product | |||||||||

| 1 | □ ↓ |

Rubber material | visual | / | / | / | ||||

| 2 |

◇ ↓ |

IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | |||||||

| Tensile machine | elongation | / | / | |||||||

| hydrometer | The proportion of | / | / | |||||||

| Aging test chamber | The compression permanent deformation | / | / | |||||||

| 3 | □ ↓ |

Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | ◇ ↓ |

IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | ||||||||

| TS90 | / | / | ||||||||

| Hardness tester | hardness | / | ★ | |||||||

| 5 | □ ↓ |

Cutting edge /blanking |

Cutting machine | / | Is long | / | ||||

| Material weight | / | |||||||||

| 6 |

□ ↓ |

moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | ||||||||

| / | Mold temperature | ★ | ||||||||

| visual | appearance | / | / | |||||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 7 | □ ↓ |

IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 8 | □ ↓ |

deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | |||||||

| / | time | / | ||||||||

| 9 | □ ↓ |

QC | Scissors/knife | appearance | / | / | ||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

1. We are professional RUBBER SEAL manufacturer and have more than 15 years export experience in different market.

2. Have excellent quality and serving several global top 500 companies.

3. Have a strong technical team can customize rubber raw-material formula according to different needs.

4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

5. Have own mold department can finished mold process in very fast time and accept any high difficult mold.

6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.

A: Different product the MOQ was different, usually one size order amount match 150USD.

A: Yes, we have OEM/ODM service.

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment.

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

A: Yes, once order make sure we can supply free samples and afford delivery cost.