|

1.Raw-Material Brand: |

DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M |

|

2.Type: |

According to Car Brand or customize |

|

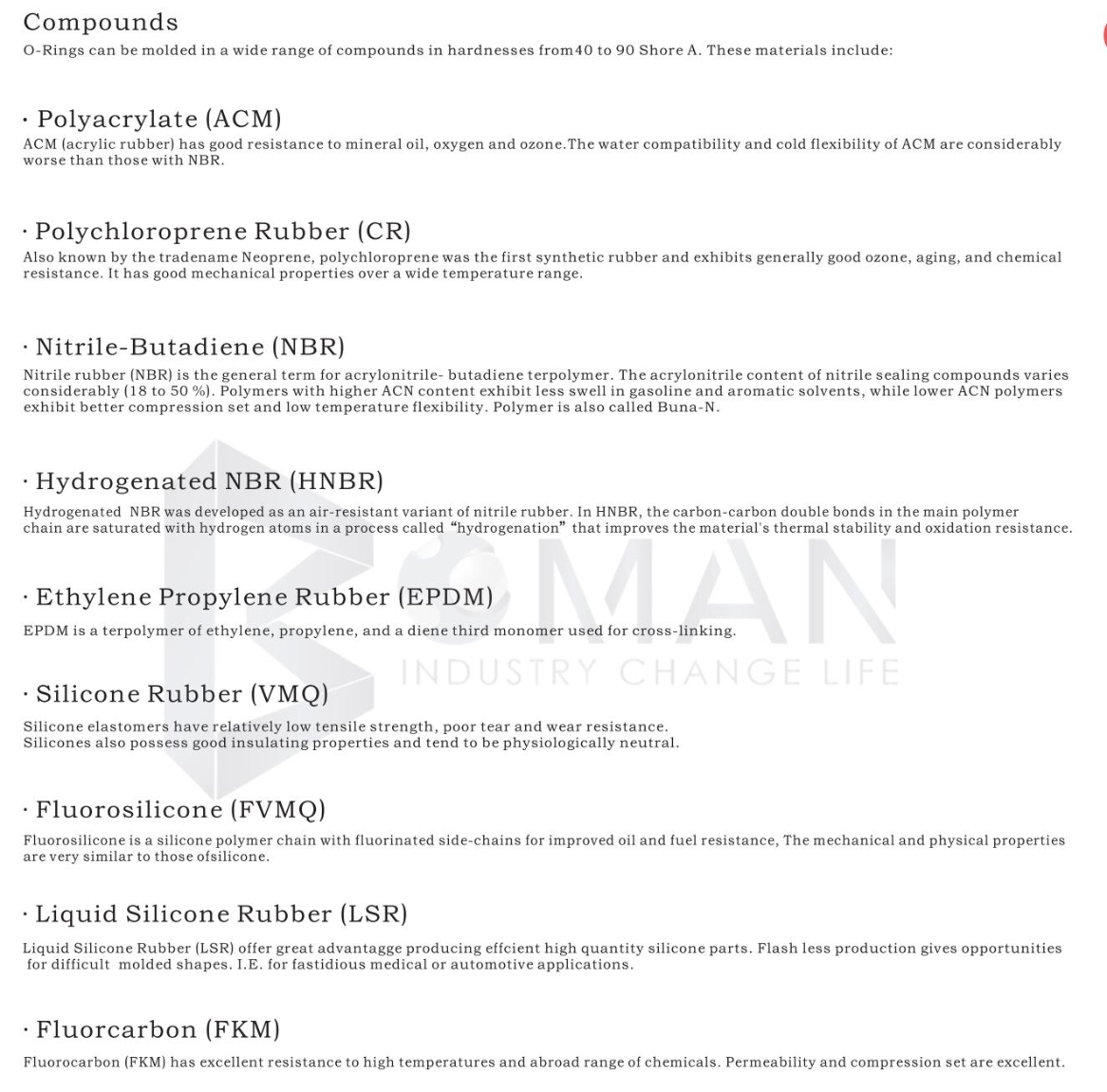

3.Material Type: |

NBR / FKM / Silicone/EPDM/HNBR... |

|

4.Size: |

Standard and Customize |

|

5.Products Application |

Metallurgical, chemical, engineering, construction, mining, petroleum machinery |

|

6.Color: |

Black, white, red, or any customize |

|

7.Parameters: |

Temperature from -60° C to +220° C in different material |

|

8.Factory Certificate |

IATF 16949:2016 and ISO9001, ISO14001 certificated |

|

9.Product Certificate |

KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA |

Rubber bellows, also known as expansion joints or flexible connectors, are specialized components designed to accommodate movement, vibration, and misalignment in various industrial applications. They are typically made from elastomeric materials like natural rubber, neoprene, EPDM, or silicone, which offer excellent elasticity and resilience. The primary purpose of rubber bellows is to provide a flexible and sealed connection between two rigid components, allowing them to move independently while maintaining a leak-tight seal. This flexibility is vital in situations where thermal expansion and contraction, vibration, or mechanical movements occur, as it helps prevent damage to equipment and ensures the overall system's integrity.

1.Flexibility and Movement: Rubber bushing can flex, bend, and elongate to accommodate movement and misalignment in mechanical systems. They allow for axial, lateral, and angular movement, making them suitable for applications where dynamic movement or vibration is present.

2.Vibration and Noise Reduction: Rubber bushing act as vibration isolators, dampening and reducing vibrations transmitted between connected components. They help minimize noise and improve the overall comfort and safety of machinery and equipment.

3.Expansion and Contraction Compensation: Rubber bushing can absorb thermal expansion and contraction in piping systems, machinery, and equipment. They prevent damage caused by thermal stresses and extend the lifespan of components.

4.Leak Prevention: Rubber bushing form a flexible and airtight seal, preventing the leakage of gases, liquids, or dust between connected parts. They maintain system integrity and reduce the risk of contamination or environmental issues.

5.Corrosion Resistance: High-quality rubber bellows are resistant to corrosion, chemicals, and many fluids, making them suitable for use in harsh environments and aggressive media.

6.Lightweight and Easy Installation: Rubber bushing are lightweight and easy to install compared to more rigid compensators or expansion joints. Their flexibility allows for quick and straightforward installation in various applications.

7.Cost-Effective Solution: Rubber bushing offer a cost-effective alternative to more complex mechanical solutions for accommodating movement, thermal expansion, or vibration. They reduce the need for expensive custom engineering and maintenance.

8.Versatility: Rubber bushing are available in various sizes, shapes, and materials, making them versatile and suitable for a wide range of applications across different industries.

9.Low Maintenance: Once installed, rubber bellows generally require minimal maintenance. They are designed to withstand wear, tear, and aging, ensuring long service life and reducing maintenance costs.

10.Customization: Rubber bushing can be custom designed to meet specific application requirements, such as size, movement capacity, pressure ratings, and temperature ranges.

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | product | |||||||||

| 1 | □ ↓ |

Rubber material | visual | / | / | / | ||||

| 2 |

◇ ↓ |

IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | |||||||

| Tensile machine | elongation | / | / | |||||||

| hydrometer | The proportion of | / | / | |||||||

| Aging test chamber | The compression permanent deformation | / | / | |||||||

| 3 | □ ↓ |

Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | ◇ ↓ |

IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | ||||||||

| TS90 | / | / | ||||||||

| Hardness tester | hardness | / | ★ | |||||||

| 5 | □ ↓ |

Cutting edge /blanking |

Cutting machine | / | Is long | / | ||||

| Material weight | / | |||||||||

| 6 |

□ ↓ |

moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | ||||||||

| / | Mold temperature | ★ | ||||||||

| visual | appearance | / | / | |||||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 7 | □ ↓ |

IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 8 | □ ↓ |

deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | |||||||

| / | time | / | ||||||||

| 9 | □ ↓ |

QC | Scissors/knife | appearance | / | / | ||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

1.Piping Systems: Rubber bellows are often used to compensate for thermal expansion and contraction in piping systems. They allow for movement and flexibility, reducing the stress on the piping and associated equipment. This is crucial in applications where temperature fluctuations are common, such as in HVAC systems, power plants, and industrial pipelines.

2.Automotive Industry: In automobiles, rubber bellows are used in various components, such as air intake systems, exhaust systems, and suspension systems. They help absorb vibrations and movements, reducing noise and enhancing overall vehicle performance.

3.Aerospace and Aviation: Rubber bellows find applications in aircraft and spacecraft to provide flexibility in ducting systems, allowing for movement during flight and thermal changes. They also help reduce vibration and mechanical stresses in critical components.

4.Manufacturing Equipment: In manufacturing processes, rubber bellows are used in machinery to isolate vibrations, compensate for misalignments, and provide flexible connections in material handling systems and equipment like pumps, compressors, and conveyors.

5.Marine Industry: In marine applications, rubber bellows are used in exhaust systems, cooling systems, and bilge pump connections to accommodate movements and vibrations while maintaining a watertight seal.

6.Medical Devices: Rubber bellows are used in medical equipment and devices to provide flexible connections, allowing for movement and positioning while maintaining sterility and sealing.

7.Vacuum Technology: In vacuum systems, rubber bellows help compensate for changes in pressure and temperature while maintaining a leak-tight seal.

8.Chemical Processing: Rubber bellows are used in chemical plants to absorb movement and stress in piping systems handling corrosive and aggressive chemicals.

9.Mining and Construction: In heavy machinery used in mining and construction, rubber bellows are used to dampen vibrations and protect critical components from misalignment and stress.

10.Agricultural Machinery: In agricultural equipment, rubber bellows are utilized to provide flexible connections and protect machinery from shocks and vibrations during operation.

1. We are professional RUBBER SEAL manufacturer and have more than 15 years export experience in different market.

2. Have excellent quality and serving several global top 500 companies.

3. Have a strong technical team can customize rubber raw-material formula according to different needs.

4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

5. Have own mold department can finished mold process in very fast time and accept any high difficult mold.

6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.

A: Different product the MOQ was different, usually one size order amount match 150USD.

A: Yes, we have OEM/ODM service.

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment.

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

A: Yes, once order make sure we can supply free samples and afford delivery cost.