|

1.Raw-Material Brand: |

DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M |

|

2.Type: |

According to Car Brand |

|

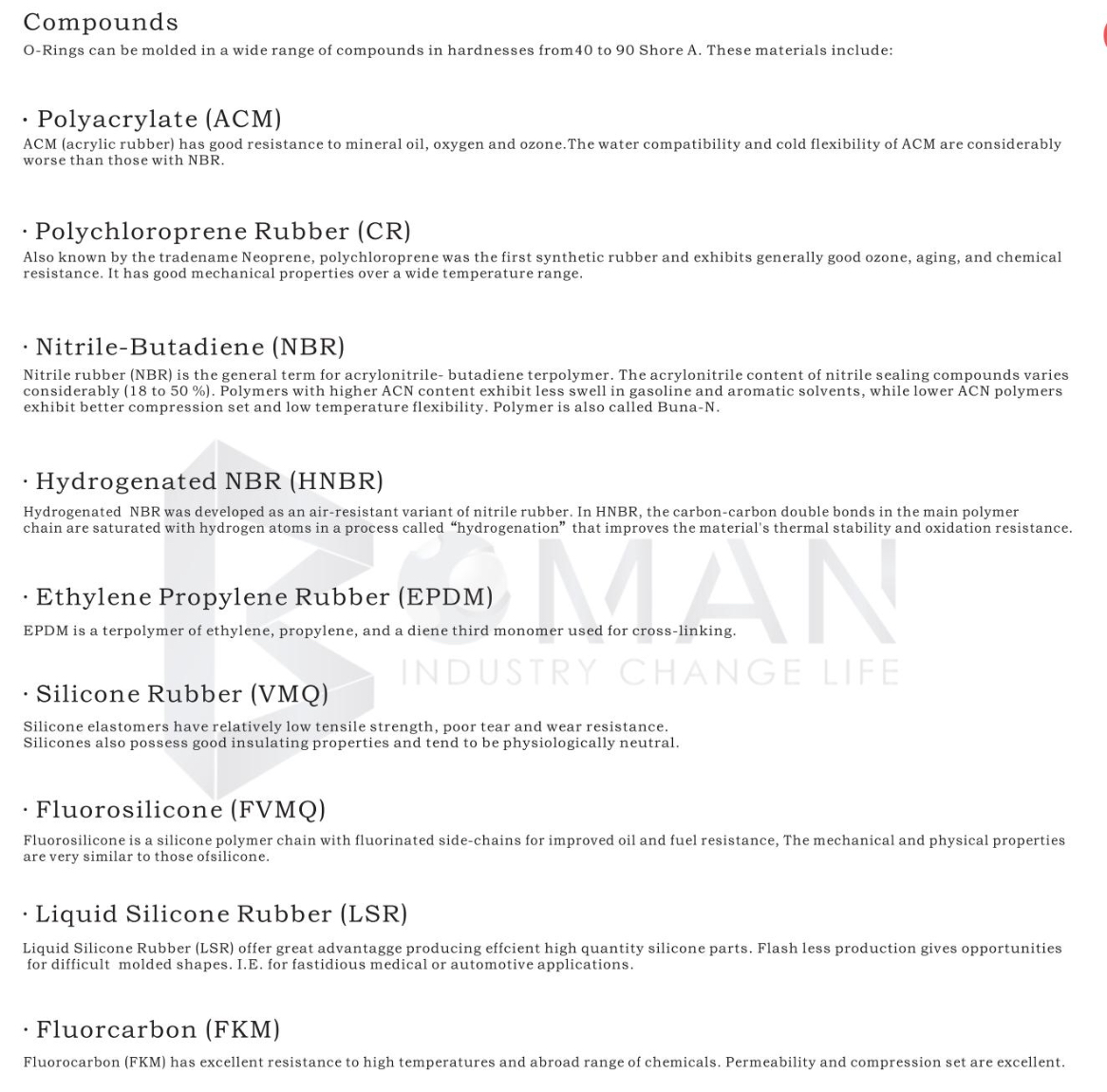

3.Material Type: |

NBR / FKM / Silicone |

|

4.Size: |

Standard size and Custom Size Accepted |

|

5.Products Application |

Metallurgical, chemical, engineering, construction, mining, petroleum machinery |

|

6.Color: |

Black, white, red, green, or any customize |

|

7.Parameters: |

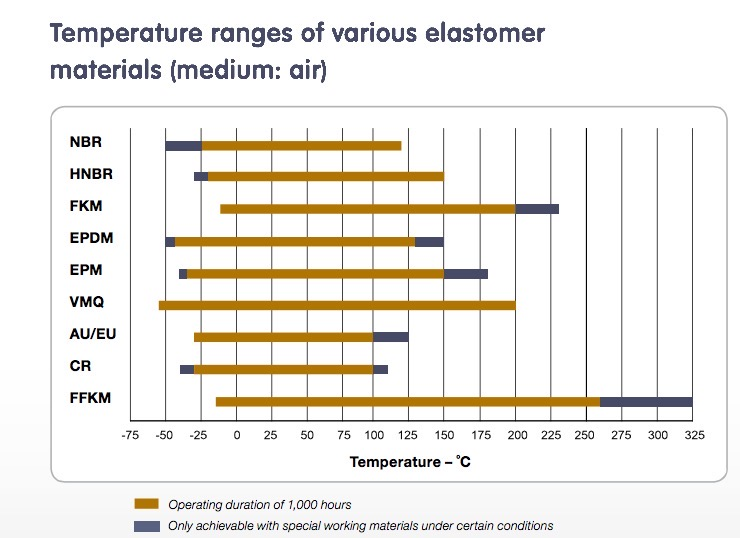

Temperature from -60° C to +220° C in different material |

|

8.Factory Certificate |

IATF 16949:2016 and ISO9001, ISO14001 certificated |

|

9.Product Certificate |

KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA |

Motorcycle valve stem seals are essential components located in the engine's cylinder head, specifically around the valve stems. These seals play a crucial role in regulating the flow of engine oil and providing a reliable seal for the engine's valves. They are a vital part of the valve train system in all types of motorcycles, ranging from small scooters to high-performance sport bikes and touring motorcycles.

1.Oil Control: Valve stem seals help control the flow of engine oil into the combustion chamber. They prevent excessive oil from entering the combustion chamber during the intake stroke, which could cause oil burning and fouling of spark plugs.

2.Reduced Oil Consumption: By regulating the amount of oil entering the combustion chamber, valve stem seals help reduce oil consumption. This leads to longer intervals between oil changes and better overall engine efficiency.

3.Improved Combustion Efficiency: Properly functioning valve stem seals ensure that only air and fuel enter the combustion chamber during the intake stroke, optimizing the air-to-fuel ratio and combustion efficiency.

4.Prevented Valve Guide Wear: Valve stem seals reduce oil leakage into the valve guides, helping to prevent excessive wear on the guides and extending their lifespan.

5.Minimized Emissions: Efficient valve stem seals contribute to lower oil consumption and better combustion, resulting in reduced emissions, which is beneficial for meeting environmental regulations and improving the motorcycle's environmental impact.

6.Enhanced Engine Performance: By maintaining proper lubrication and preventing oil burning, valve stem seals help the engine run smoothly and maintain its power output, contributing to better overall performance.

7.Reduced Risk of Engine Damage: Without properly functioning valve stem seals, excessive oil leakage can lead to carbon buildup, valve sticking, and other engine issues. Well-maintained valve stem seals reduce the risk of engine damage and costly repairs.

8.Longevity: By protecting the valves, valve guides, and other engine components from excessive wear and oil contamination, valve stem seals contribute to the engine's longevity and durability.

9.Increased Valve Lifespan: With minimized oil leakage, valve stem seals help extend the lifespan of the engine's valves, reducing the need for premature valve replacements.

10.Smoother Idling: Properly functioning valve stem seals contribute to a smoother idle, as they help maintain consistent engine compression and prevent oil fouling in the combustion chamber.

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | product | |||||||||

| 1 | □ ↓ |

Rubber material | visual | / | / | / | ||||

| 2 |

◇ ↓ |

IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | |||||||

| Tensile machine | elongation | / | / | |||||||

| hydrometer | The proportion of | / | / | |||||||

| Aging test chamber | The compression permanent deformation | / | / | |||||||

| 3 | □ ↓ |

Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | ◇ ↓ |

IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | ||||||||

| TS90 | / | / | ||||||||

| Hardness tester | hardness | / | ★ | |||||||

| 5 | □ ↓ |

Cutting edge /blanking |

Cutting machine | / | Is long | / | ||||

| Material weight | / | |||||||||

| 6 |

□ ↓ |

moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | ||||||||

| / | Mold temperature | ★ | ||||||||

| visual | appearance | / | / | |||||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 7 | □ ↓ |

IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 8 | □ ↓ |

deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | |||||||

| / | time | / | ||||||||

| 9 | □ ↓ |

QC | Scissors/knife | appearance | / | / | ||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

1.Intake and Exhaust Valves: Valve stem seals are applied to both the intake and exhaust valves in motorcycle engines. They are responsible for controlling the flow of engine oil around the valve stems and ensuring that only air and fuel (during the intake stroke) or exhaust gases (during the exhaust stroke) enter the combustion chamber.

2.Internal Combustion Engines: Motorcycle valve stem seals are used in all types of internal combustion engines, including two-stroke and four-stroke engines. They are present in both air-cooled and liquid-cooled engines, regardless of the engine's configuration.

3.Racing and High-Performance Motorcycles: High-performance and racing motorcycles often place even higher demands on valve stem seals due to increased engine speeds and temperatures. Specialized performance valve stem seals may be used in these applications to handle the additional stresses.

4.Cruisers and Touring Bikes: Valve stem seals are also found in cruiser motorcycles and touring bikes, where long-distance reliability is crucial. They contribute to improved fuel efficiency and reduced oil consumption during extended rides.

5.Dirt Bikes and Off-Road Motorcycles: In off-road motorcycles and dirt bikes, valve stem seals play a vital role in preventing dust, dirt, and debris from entering the engine during off-road riding conditions.

6.Scooters and Commuter Bikes: Even small-displacement scooters and commuter motorcycles benefit from the use of valve stem seals to reduce oil consumption and emissions, ensuring efficient and reliable engine operation.

7.Older Motorcycle Restoration: During the restoration of vintage or classic motorcycles, replacing worn-out valve stem seals is often a crucial step in ensuring the engine's proper function and longevity.

1. We are professional RUBBER SEAL manufacturer and have more than 15 years export experience in different market.

2. Have excellent quality and serving several global top 500 companies.

3. Have a strong technical team can customize rubber raw-material formula according to different needs.

4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

5. Have own mold department can finished mold process in very fast time and accept any high difficult mold.

6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.

A: Different product the MOQ was different, usually one size order amount match 150USD.

A: Yes, we have OEM/ODM service.

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment.

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

A: Yes, once order make sure we can supply free samples and afford delivery cost.