|

1.Raw-Material Brand: |

DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M |

|

2.Type: |

Extrusion Strip, Cord |

|

3.Material Type: |

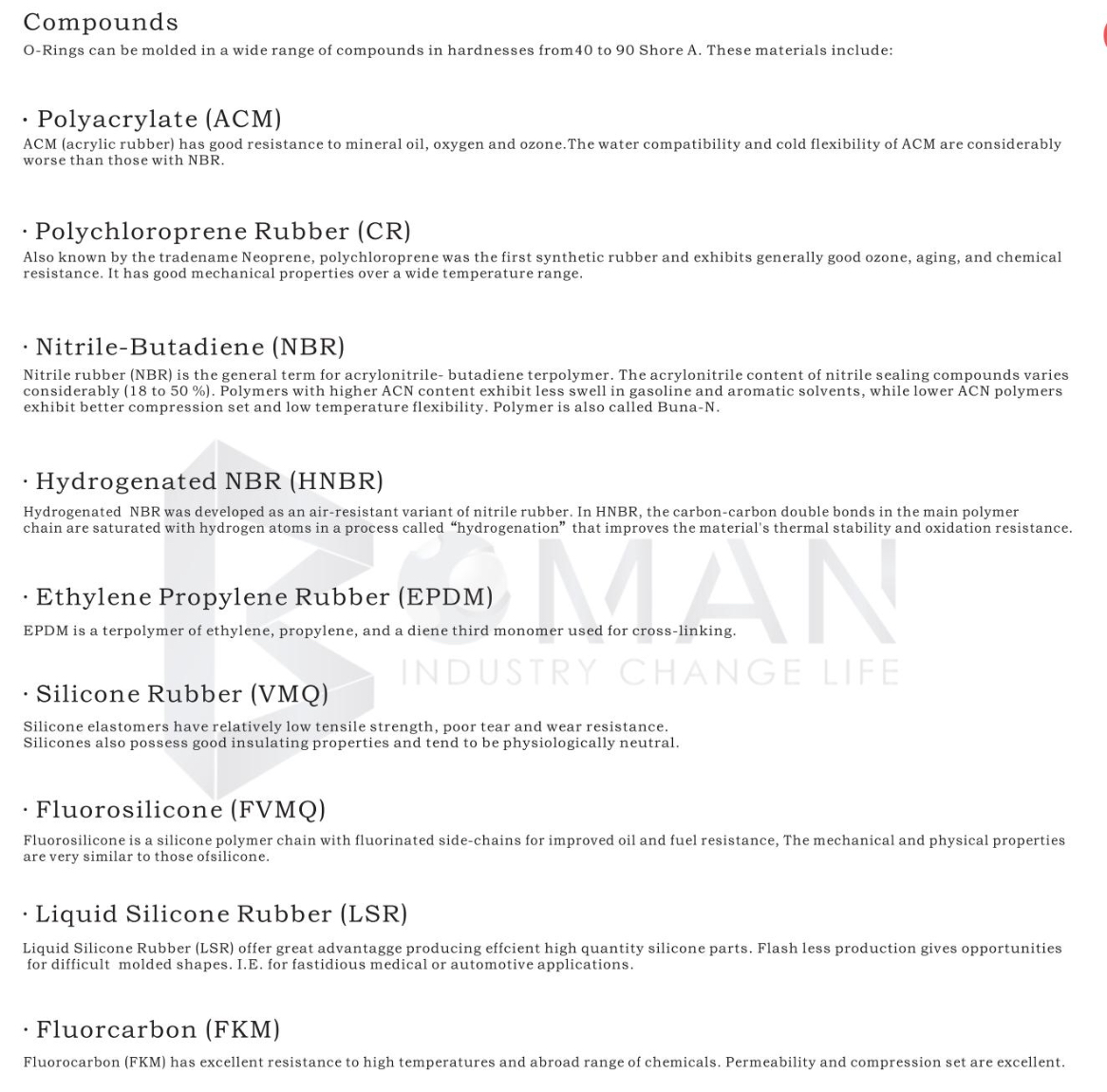

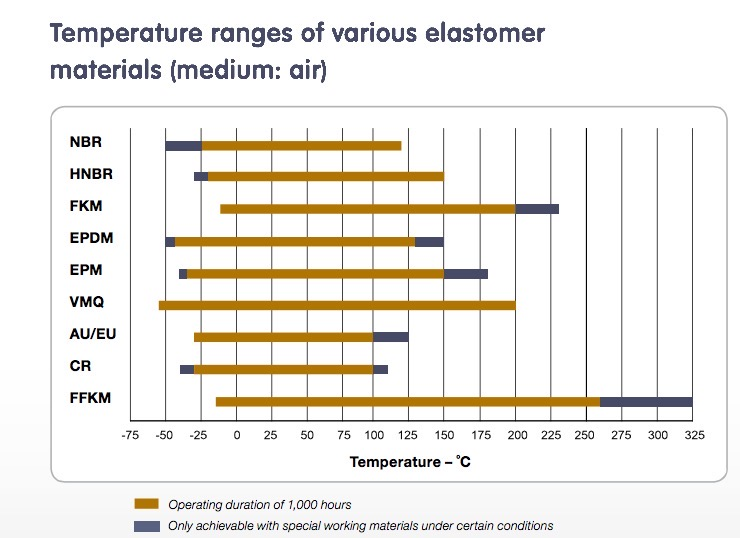

NBR / FKM / Silicone/EPDM/EVA/PVC |

|

4.Size: |

Standard size and Custom Size Accepted |

|

5.Products Application |

Metallurgical, chemical, engineering, construction, mining, petroleum machinery |

|

6.Color: |

Black, white, red, or any customize |

|

7.Parameters: |

Temperature from -60° C to +220° C in different material |

|

8.Factory Certificate |

IATF 16949:2016 and ISO9001, ISO14001 certificated |

|

9.Product Certificate |

KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA |

Door and window sealing strips, also known as weatherstrips or weather seals, are specialized components designed to seal gaps and joints around doors and windows. They are commonly made from materials such as rubber, silicone, PVC, foam, or felt, and are installed along the edges of doors and windows to create a tight and effective barrier against external elements.

1.Energy Efficiency: Sealing strips help improve the energy efficiency of buildings by preventing drafts and air leaks around doors and windows. They create a tight seal, reducing the loss of heated or cooled air and minimizing the need for excessive heating or cooling, leading to energy cost savings.

2.Temperature Regulation: Sealing strips create a barrier against outside temperatures, keeping indoor spaces more comfortable throughout the year. In cold weather, they help prevent cold drafts, and in hot weather, they minimize heat transfer, contributing to a more pleasant indoor environment.

3.Noise Reduction: Sealing strips act as sound barriers, reducing the infiltration of external noise into indoor spaces and creating a quieter and more peaceful environment.

4.Dust and Insect Protection: Sealing strips block the entry of dust, dirt, and insects, helping to maintain cleaner indoor spaces and enhancing overall hygiene.

5.Moisture Resistance: Some sealing strips have moisture-resistant properties, preventing water infiltration during rain or damp conditions and protecting the interior from potential water damage.

6.UV and Weather Resistance: High-quality sealing strips are often UV and weather-resistant, ensuring that they maintain their effectiveness and appearance over time, even in harsh outdoor conditions.

7.Easy Installation: Sealing strips are typically easy to install and can be applied to various door and window types, including hinged doors, sliding doors, casement windows, and more.

8.Longevity: Properly installed and maintained, sealing strips can have a long service life, providing continuous protection and insulation for many years.

9.Cost-Effective: Door and window sealing strips offer a cost-effective solution to improve insulation and energy efficiency, helping to lower heating and cooling costs in the long run.

10.Versatility: Sealing strips come in various shapes, sizes, and materials, making them suitable for a wide range of door and window applications, including residential, commercial, and industrial settings

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | product | |||||||||

| 1 | □ ↓ |

Rubber material | visual | / | / | / | ||||

| 2 |

◇ ↓ |

IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | |||||||

| Tensile machine | elongation | / | / | |||||||

| hydrometer | The proportion of | / | / | |||||||

| Aging test chamber | The compression permanent deformation | / | / | |||||||

| 3 | □ ↓ |

Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | ◇ ↓ |

IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | ||||||||

| TS90 | / | / | ||||||||

| Hardness tester | hardness | / | ★ | |||||||

| 5 | □ ↓ |

Cutting edge /blanking |

Cutting machine | / | Is long | / | ||||

| Material weight | / | |||||||||

| 6 |

□ ↓ |

moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | ||||||||

| / | Mold temperature | ★ | ||||||||

| visual | appearance | / | / | |||||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 7 | □ ↓ |

IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 8 | □ ↓ |

deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | |||||||

| / | time | / | ||||||||

| 9 | □ ↓ |

QC | Scissors/knife | appearance | / | / | ||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

1.Residential Buildings: Sealing strips are extensively used in homes and residential buildings to improve energy efficiency and comfort. They are applied around exterior doors and windows to prevent drafts, reduce energy loss, and create a more comfortable indoor environment.

2.Commercial Buildings: In commercial buildings, such as offices, hotels, and retail spaces, sealing strips are used to ensure proper insulation and temperature regulation. They help maintain a comfortable atmosphere for occupants and reduce energy costs.

3.Industrial Facilities: Sealing strips are employed in industrial facilities to seal access points, such as industrial doors and loading dock doors. They help prevent the infiltration of dust, pests, and outside weather conditions into the working areas.

4.Automotive Industry: In the automotive sector, sealing strips are used to seal gaps and joints around car doors, windows, and trunks. They help improve the vehicle's aerodynamics, reduce noise, and protect the interior from water and dust.

5.Aerospace: Sealing strips are utilized in the aerospace industry to ensure airtight seals for aircraft doors, windows, and access panels. They help maintain cabin pressure and protect against external environmental conditions.

6.Marine: In boats and ships, sealing strips are applied to windows, hatches, and doors to prevent water infiltration, improve insulation, and provide a comfortable interior environment.

7.HVAC and Refrigeration: Sealing strips are used in HVAC systems and refrigeration equipment to seal access panels, ductwork, and other openings, ensuring proper insulation and reducing energy consumption.

8.Electrical Enclosures: Sealing strips are employed in electrical enclosures to provide a dust-proof and moisture-resistant seal, protecting sensitive electrical components.

9.Agricultural Buildings: Sealing strips are used in agricultural buildings, such as barns and storage facilities, to seal doors and windows and maintain a controlled environment for livestock and crops.

10.Greenhouses: Sealing strips are applied to greenhouse doors and windows to regulate temperature and humidity levels, creating an optimal growing environment for plants.

1. We are professional RUBBER SEAL manufacturer and have more than 15 years export experience in different market.

2. Have excellent quality and serving several global top 500 companies.

3. Have a strong technical team can customize rubber raw-material formula according to different needs.

4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

5. Have own mold department can finished mold process in very fast time and accept any high difficult mold.

6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.

A: Different product the MOQ was different, usually one size order amount match 150USD.

A: Yes, we have OEM/ODM service.

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment.

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

A: Yes, once order make sure we can supply free samples and afford delivery cost.