|

1.Raw-Material Brand: |

DuPont (US) / Dow Corning (Germany) / Bayer (Germany) / 3M |

|

2.Type: |

According to Car Brand |

|

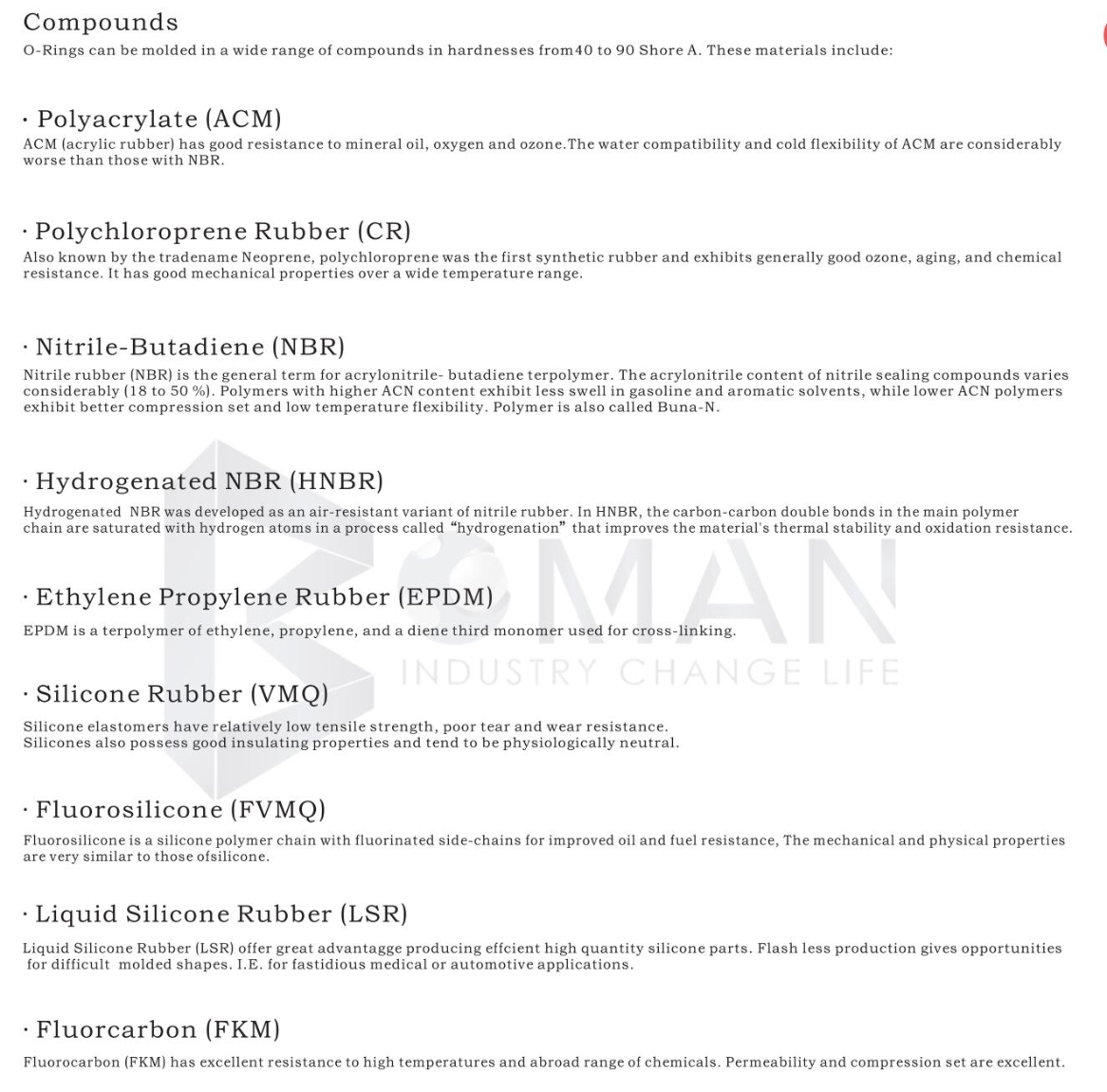

3.Material Type: |

NBR / FKM / Silicone/EPDM/HNBR... |

|

4.Size: |

Standard and Customize |

|

5.Products Application |

Metallurgical, chemical, engineering, construction, mining, petroleum machinery |

|

6.Color: |

Black, white, red, or any customize |

|

7.Parameters: |

Temperature from -60° C to +220° C in different material |

|

8.Factory Certificate |

IATF 16949:2016 and ISO9001, ISO14001 certificated |

|

9.Product Certificate |

KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA |

Automotive rubber parts refer to a wide range of rubber components used in vehicles to provide sealing, vibration isolation, cushioning, and other functional properties. These rubber parts play a crucial role in ensuring the performance, safety, and comfort of automobiles. It was including:Seals and Gaskets,Mounts and Bushings,Hoses and Tubing,Anti-vibration Components,Weatherstripping

They are designed to withstand the demanding conditions of the automotive environment, including exposure to extreme temperatures, chemicals, oils, fuels, and mechanical stresses. They are typically made from elastomeric materials, such as natural rubber or synthetic rubber compounds, that exhibit excellent flexibility, resilience, and durability.

1.Sealing Capabilities: Rubber parts, such as seals and gaskets, provide effective sealing solutions in various automotive applications. They create a tight and reliable seal between components, preventing leakage of fluids, gases, and noise. Rubber seals and gaskets ensure the integrity and performance of critical systems, such as the engine, transmission, cooling system, and fuel system.

2.Vibration Isolation: Rubber mounts, bushings, and anti-vibration components are designed to isolate vibrations and dampen shocks in the automotive environment. These rubber parts absorb and dissipate vibrations, reducing the transfer of noise and vibration to the vehicle's body and occupants. This helps enhance ride comfort, reduce driver fatigue, and protect sensitive components from excessive vibrations.

3.Flexibility and Resilience: Automotive rubber parts exhibit excellent flexibility and resilience, allowing them to withstand mechanical stresses, temperature variations, and dynamic movements. They can flex, deform, and return to their original shape, ensuring long-lasting performance and durability in demanding automotive applications. The inherent elasticity of rubber parts enables them to absorb impacts and adapt to changing conditions.

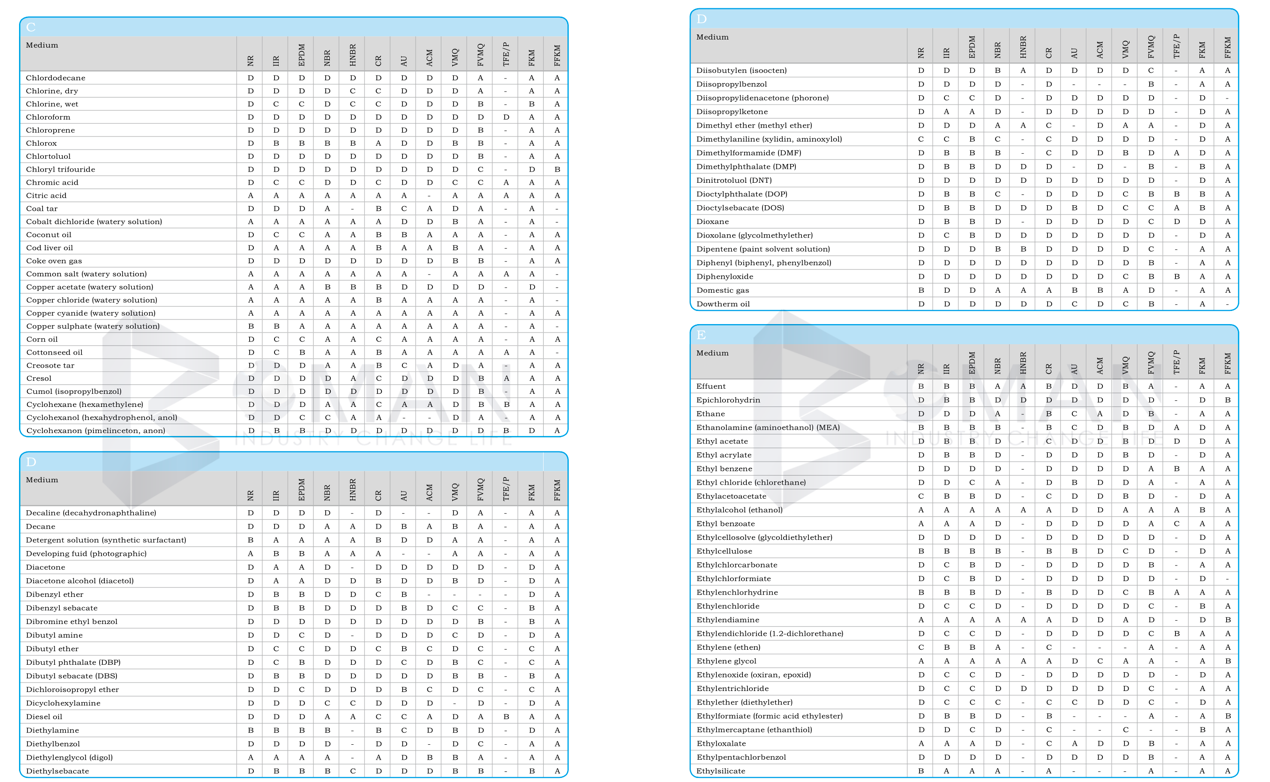

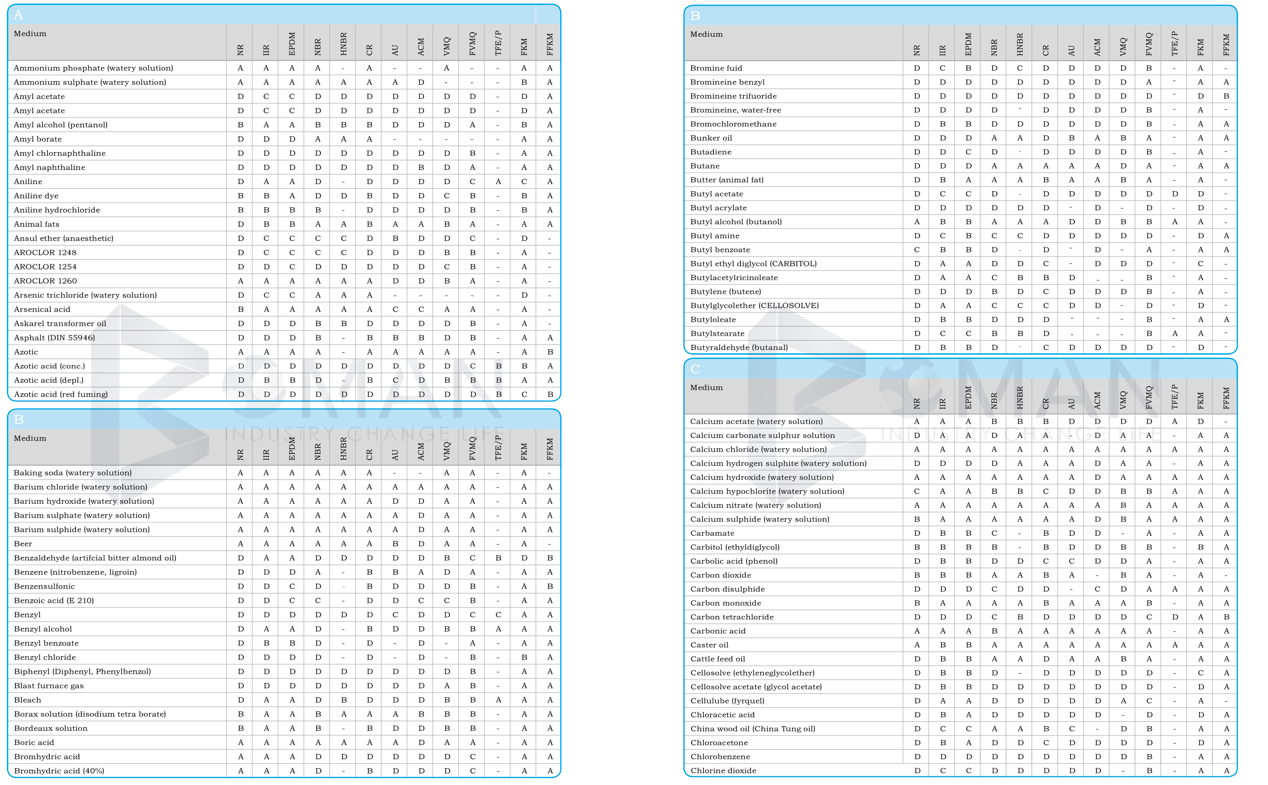

4.Chemical and Environmental Resistance: Rubber parts used in vehicles are designed to resist degradation and damage caused by exposure to various chemicals, oils, fuels, and environmental factors. They can withstand the harsh conditions of the automotive environment, including high temperatures, UV radiation, moisture, and ozone. This resistance ensures the longevity and reliability of rubber parts in automotive applications.

5.Noise and Vibration Reduction: The inherent damping properties of rubber help reduce noise and vibrations generated by engine operation, road conditions, and other sources. Rubber mounts, bushings, and anti-vibration components effectively absorb and dissipate vibrations, minimizing noise transmission to the vehicle's interior. This contributes to a quieter and more comfortable driving experience.

6.Easy Installation and Maintenance: Automotive rubber parts are designed for easy installation, replacement, and maintenance. They often have simple designs and can be quickly installed or removed without the need for specialized tools or complex procedures. This facilitates efficient repair and maintenance operations, reducing downtime and associated costs.

7.Cost-Effectiveness: Rubber parts offer a cost-effective solution for automotive applications. They are generally affordable, readily available, and can be manufactured in large quantities. The durability and longevity of rubber parts contribute to their cost-effectiveness by reducing the need for frequent replacements and repairs.

8.Design Flexibility: Rubber parts can be molded or shaped into various sizes, shapes, and configurations to suit specific automotive applications. This design flexibility allows manufacturers to customize rubber components according to the specific requirements of vehicles, systems, and components. Rubber parts can be tailored to fit unique geometries, ensuring optimal sealing, vibration isolation, and performance.

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | product | |||||||||

| 1 | □ ↓ |

Rubber material | visual | / | / | / | ||||

| 2 |

◇ ↓ |

IQC | Hardness tester | hardness | / | ★ | ||||

| Tensile machine | Tensile strength | / | / | |||||||

| Tensile machine | elongation | / | / | |||||||

| hydrometer | The proportion of | / | / | |||||||

| Aging test chamber | The compression permanent deformation | / | / | |||||||

| 3 | □ ↓ |

Mixing | mixer | / | Material thicknessmm | / | ||||

| 4 | ◇ ↓ |

IQC | rheometer | TS2 | / | / | ||||

| TS50 | / | / | ||||||||

| TS90 | / | / | ||||||||

| Hardness tester | hardness | / | ★ | |||||||

| 5 | □ ↓ |

Cutting edge /blanking |

Cutting machine | / | Is long | / | ||||

| Material weight | / | |||||||||

| 6 |

□ ↓ |

moulding | 300 t hot molding machine, automatic monitoring | / | The molding pressure (kgcm2) | ★ | ||||

| / | Molding time | ★ | ||||||||

| / | Mold temperature | ★ | ||||||||

| visual | appearance | / | / | |||||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 7 | □ ↓ |

IPQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 8 | □ ↓ |

deflashing | visual | appearance | / | / | ||||

| Automatic disassembly machine | / | speed | / | |||||||

| / | time | / | ||||||||

| 9 | □ ↓ |

QC | Scissors/knife | appearance | / | / | ||||

| steps | The process flow | Process flow name | Machinery and equipment/measuring equipment | features | Special features symbols | note | ||||

| product | process | |||||||||

| 10 | ◇ ↓ |

FQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| 11 | □ ↓ |

cleaning | Plastic basket | / | / | / | Manual cleaning | |||

| / | / | / | ||||||||

| / | / | / | ||||||||

| 12 | □ ↓ |

Post curing | The oven | / | time | ★ | ||||

| / | The temperature | ★ | ||||||||

| 13 | □ ↓ |

Packing | Electronic says | Single - | / | / | ||||

| Baling press | The number of | / | / | |||||||

| The printer | The labe | / | / | |||||||

| visual | The cartons | / | / | |||||||

| 14 | ◇ ↓ |

OQC | visual | appearance | / | / | ||||

| Hardness tester | hardness | / | ★ | |||||||

| The projector/caliper | size | / | ★ | |||||||

| visual | check | / | / | |||||||

| visual | weighing | / | / | |||||||

| 15 | □ | Warehousing /delivery |

transport cart | Delivery note | / | / | ||||

| Courier | / | / | ||||||||

| Put in storage | / | / | ||||||||

| note | 1.“◇”Said inspection、“□”Said processing、“↓”Said handling、“△”Said storage、“▲”Said reworking/repairing | |||||||||

| 2.“★”Said product function and process of key special feature symbol; | ||||||||||

1.Engine Components: Rubber parts are used in engine components to provide sealing and vibration isolation. This includes gaskets for cylinder heads, valve covers, oil pans, and intake manifolds. Rubber mounts and bushings are employed in engine mounts, ensuring proper alignment and dampening vibrations.

2.Suspension System: Rubber parts play a crucial role in the suspension system of vehicles. They are used in bushings, mounts, and bump stops to absorb shocks, reduce vibrations, and provide cushioning. Rubber components ensure a smoother ride and enhance handling capabilities.

3.Cooling System: Rubber hoses and gaskets are used in the cooling system to transport coolant and maintain proper temperature control. Rubber radiator hoses connect the engine to the radiator, while gaskets ensure a tight seal in components such as the water pump, thermostat housing, and radiator.

4.Fuel System: Automotive rubber parts are utilized in the fuel system for sealing and vibration isolation. Rubber seals and gaskets are employed in fuel injectors, fuel pumps, fuel tanks, and fuel lines to prevent leaks and maintain system integrity.

5.Transmission System: Rubber parts are found in the transmission system, including gaskets and seals in transmission pans, torque converters, and transmission housing. They provide effective sealing to prevent fluid leaks and ensure proper transmission performance.

6.Door and Window Seals: Rubber seals and weatherstripping are used in doors and windows to create a watertight and airtight seal. These seals prevent water, dust, and noise from entering the vehicle's interior, enhancing comfort and reducing wind noise.

7.HVAC System: Rubber components are employed in the HVAC (Heating, Ventilation, and Air Conditioning) system of vehicles. Rubber seals and gaskets provide proper sealing in HVAC components, including air conditioning compressors, evaporator cores, and heater cores.

8.Brake System: Rubber parts play a role in the braking system, particularly in brake hoses and seals. Rubber brake hoses transport brake fluid to the braking components, while seals ensure a proper seal in brake calipers, wheel cylinders, and master cylinders.

9.Electrical System: Rubber components, such as grommets and seals, are used in the electrical system to provide insulation and protection. They are found in wire harnesses, connectors, and electrical enclosures, safeguarding electrical connections from moisture, dust, and other contaminants.

10.Body Seals: Rubber seals and gaskets are applied throughout the vehicle's body to provide sealing and insulation. They are used in areas such as the trunk, hood, doors, sunroof, and windows, ensuring a secure and weatherproof seal.

These are just a few examples of the wide range of applications for automotive rubber parts. They are integral to the functioning, performance, and safety of various components and systems in vehicles, contributing to a comfortable and reliable driving experience.

1. We are professional RUBBER SEAL manufacturer and have more than 15 years export experience in different market.

2. Have excellent quality and serving several global top 500 companies.

3. Have a strong technical team can customize rubber raw-material formula according to different needs.

4. Have perfect After-Sales team, once cargo have problem will be 100% recall in the first time.

5. Have own mold department can finished mold process in very fast time and accept any high difficult mold.

6. Factory have IATF 16949:2016 certificated and product with: KTW-W270/ Watermark/ LFGB / RoHs/REACH/FDA certificated.

A: Different product the MOQ was different, usually one size order amount match 150USD.

A: Yes, we have OEM/ODM service.

A: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo. Old customer no need advance desposit payment.

A: Usually it was 15-20days finished order, if summer season due to high temperature the lead time need 30days

A: Yes, once order make sure we can supply free samples and afford delivery cost.